Sugar Dissolving Tank Vessel

Specifications

Sugar Dissolving Tank also named invert sugar tank, widely apply to food, beverage,dairy products,chemical etc industry.

Sugar Dissolving Tank are mainly suitable for dissolving white granulated sugar, also use to melt milk powder, starch etc powder or granular materials.It also play some functions as stirring,dissolving, heating( or cooling, use tap-water cooling), filtrating( strainer) and others.Fast melting speed, high efficiency, is the one of technology equipment for food, drink productions.

Suger Dissolving Tank prepared for series of advantages like convenient to operate, corrosion resistance, powerful production ability, easy to clean and maintenance. External tank body is the stainless steel which was polished and processed to more bright and smooth of the surface of tank.

Sugar Dissolving Tank Working Principle:

Suger dissolving tank primarily put dissolved materials and cool water(or hot-water) in tank , and then steam inlet inter-layer to reach the effects through heated dissolving.

1. This tank is suitable for melting granularity sugar into syrup, involve in food industry , pharmaceutical etc. some food as confetti, sprinkles , and tablet need to coat sugar , these will need to sugar melting tank . Because this product need add syrup into it to polish.

2. Top stirring, bottom discharge hole, easy to operate, convenient for cleaning

3. With four legs as support, it is more stability.

4. It is very popular for use for food industry, pharmaceutical plant and etc.

5. triple -layer, the inner layer is touch materials, the middle layer is heating, and the outer -layer is insulation.

Sugar Dissolving Tank’s application:

1.Food process such as juice ,beverage ,milk and pure water ,sugar so on

2.Pharmaceutic process field

3.Chemical industry

4.Bio engineering

The detailed design is according to site dimension and technical requirement to design .

|

Suger Dissolving Tank |

|

|

Material: |

SS304 or SS316L or Duplex stainless or 904L |

|

Design Pressure: |

-1 -10 Bar (g) or ATM B9 |

|

Work Temperature: |

0-200 °C |

|

Volumes: |

50~30000L |

|

Construction : |

Vertical type or horizontal |

|

Jacket type : |

Dimple jacket, full jacket, or coil jacket |

|

Structure : |

Single layer vessel, vessel with jacket, vessel with jacket and insulation |

|

Heating or cooling function |

According to the heating or cooling requirement , the tank will have jacket for required function |

|

Optional Motor: |

ABB, Siemens, SEW or Indian brand |

|

Surface Finish: |

Mirror Polish or Matt polish or Acid wash&pickling or 2B |

|

Standard components : |

Manhole,sight glass , cleaning ball |

|

Optional components : |

Vent filter, Temp. Gauge, display on the gauge directly on the vessel Temp sensor PT100, digital display on the control cabinet by instrument Temp sensor with control for heating and cooling Level gauge with digital display on the control cabinet by instrument Load cell Valves |

|

Applications: |

Wine, Beer Juices Food & Beverage Pharmaceutical Biotechnology & Laboratory Medical &Medical Device Chemical Industry Painting Industrial |

Dissolving Tank

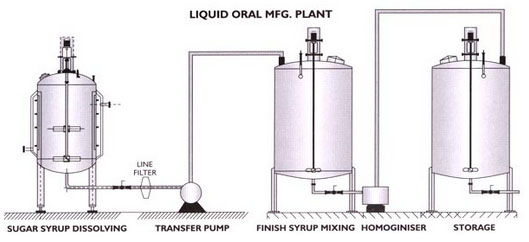

In the beverage industry, sugar is mostly processed as a watery solution. Therefore, the first step is the production of a standardized sugar syrup. The concentration is between 60 … 67° Brix. Discontinuous and continuous processes are applied in the beverage industry.

Discontinuous process with Dissolving Tank

For discontinuous processes mixers are used, the capacity of which can vary according to the prepared granular sugar quantity. The required quantity of well-tempered dissolving water is provided in the mixer. By means of a pneumatic or mechanical conveyor the granular sugar is fed to the mixer. When the dissolving procedure is finished, the sugar syrup is filtered and pasteurized and then, in a filtered condition, passed on to a buffer tank.

Continuous process with hot/cold dissolving tank

The continuous processes can be divided into cold and hot dissolving procedures. These procedures require a granular sugar silo and a corresponding tank capacity for sugar syrup. Granular sugar and dissolving water are fed to the dissolving tank in the desired ratio. A circulating pump ensures a homogeneous suspension. A partial flow is supplied to the buffer tank, either via a gap filter (cold dissolving) or a pasteurization (hot dissolving) with integrated filtration and de aeration.

Special features of Dissolving Tank:

High, constant product quality

Little wear, i.e. low maintenance requirements

Clean-ability of the system

| Melting Tank (dissolving Tank) | |||||||

| Model | Volume | Size | Medium Inlet/outlet | ||||

| ID | OD | L | H | ||||

| SDV-1000 | 1000L | 1100 | 1220 | 900 | 2200 | 40A | |

| SDV-2000 | 2000L | 1350 | 1470 | 1000 | 2600 | ||

| SDV-4000 | 4000L | 1700 | 1820 | 1100 | 3000 | ||

| SDV-6000 | 6000L | 1900 | 2020 | 1150 | 3450 | ||

| SDV-8000 | 8000L | 2100 | 2220 | 1300 | 3700 | ||

| SDV-10000 | 10000L | 2300 | 2420 | 1400 | 3850 | ||

| SDV-15000 | 15000L | 2700 | 2820 | 1650 | 4150 | ||