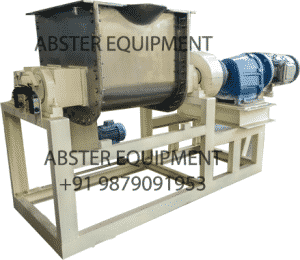

500L Silicone rubber double sigma mixer

| Port: | Ahmedabad, India |

|---|---|

| Supply Ability: | 3 Piece/Pieces per Month |

| Payment Terms: | L/C,T/T |

| Packaging Details: | Package by plywood case or according to the customer’s request. |

| Delivery Details: | Within 40 to 50 days after receiving deposit. |

| Product Type: | Paint |

| Place of Origin | Ahmedabad, India |

| Brand Name: | ABSTER |

| Model Number: | Abster-500 |

| After-sales Service Provided: | Engineers available to service machinery overseas |

| Voltage: | 220v/380V/415V/440V |

| Additional Capabilities: | Mixing, Heating, Kneading |

| Mixer Type: | Screw |

| Capacity: | 500L |

| Material: | Stainless Steel & carbon steel |

| Max. Loading capacity: | 350L |

| Power: | 22KW |

| Discharge: | screw extrusion |

| Function: | kneading machine |

|

Product Name:

500L Silicone rubber Double Sigma kneader Mixer |

| Port: | Ahmedabad, India |

|---|---|

| Supply Ability: | 10 Piece/Pieces per Month |

| Payment Terms: | L/C,T/T |

| Product Type: | Paint |

| Place of Origin: | Ahmedabad, India |

| Brand Name: | Abster |

| Model Number: | Abster-500 |

| Voltage: | 220v/380V/415V/440V |

| Additional Capabilities: | Mixing, Heating, Kneading |

| Mixer Type: | Screw |

| Capacity: | 500L |

| Material: | Stainless Steel & carbon steel |

| Max. Loading capacity: | 350L |

| Power: | 22KW |

| Discharge: | screw extrusion |

| Function: | kneading machine |

| Packaging Details: | Package by plywood case or according to the customer’s request. |

|---|---|

| Delivery Details: | Within 15-30 days after receiving deposit. |

| Abster | Abster- | ||

|

10

|

60

|

||

|

Heating mode

|

Electrical Heating

|

Electrical Heating

|

Electrical Heating

|

Sigma mixer Usage:

This kind sigma mixer machine is mainly used in high viscosity product Resins,Sealant,Silicon rubber,Glue/adhesive,Paint,Dye,BMC/CMC,Pigment,Plastics,Batteries,Tooth paste,Clay etc.

Discription:

This silicone rubber double sigma mixer machine comprises of a double ‘U’ shaped container welded and machined together inside which rotates two ‘Z’ shaped sigma blades in opposite directions. The clearances between the walls and the container are kept to a minimum to ensure maximum efficiency in kneading and mixing. The shafts of the sigma blades are fitted in bearing blocks which are each provided with roller bearings, steel glands/teflon rubber seals for smooth and leakless operations. The sigma kneader is mounted on a sturdy base frame fabricated out of ISMC sections and are free from vibrations. For cooling and heating jackets are provided.Machine equipped with suitable capacity motor & gearbox decided as per characteristics of the product & process. Equipment is provided with Jacket arrangement for heating or cooling applications. We manufacture Sigma Mixer Kneader in capacity ranging from 5 liters up to 5000 liters.

Working Principle:

Start the motor,add the material,after adding material,clean the foreign matter on the cylinder port.It takes Hydraulic Dumping up cylinder Discharge the material,it is rapid and clean to discharge.

Advantages:

1.Excellent sealing performance(copper sealing ring)

2.Simple installation-only a single power cable

3.No leakage of powder /oil-proof

4.Automatic and manual interaction

5.heating quickly, resistance of high temperature and corrosion, sanitation, environment-pollution-free, automatic heating without boiler and convenient to use etc

Company Information

Our company is specialized in manufacturing many kinds of chemical machinery such as chemical reactor, mixer machine, grinder machine etc. Our company has in good faith as the fundamental focus and product quality.

Packaging Details: Package by plywood case or according to the customer’s request.

Delivery Detail: Within 40 to 50 days after receiving deposit.

🍭 Heavy Duty Sigma Mixer Machine 🍭

#sigmamixerprice #sigmamixerpdf #sigmamixerworkingprinciple #sigmamixerwikipedia #sigmamixerforsale #sigmamixermanufacturerinmumbai #sigmamixerdesign #sigmamixermachinemanufacturers

Heavy Duty Sigma Mixer Machine is combination of mixing and kneading for highly viscous materials. Machine is having heavy duty design with suitable gauge metal in bowl, blade, cover and jacket for heavy structure to deal with high viscous product. Subsequent higher capacity motor and sturdy gearbox provided matching to product parameters. Jacket is offered with mild steel or stainless steel for heating and cooling requirements.

Optional Features/Accessories:-

Liquid Spray System

Vacuum System

Blades Cooling Arrangement

Screw System

Automatic Valve Discharging