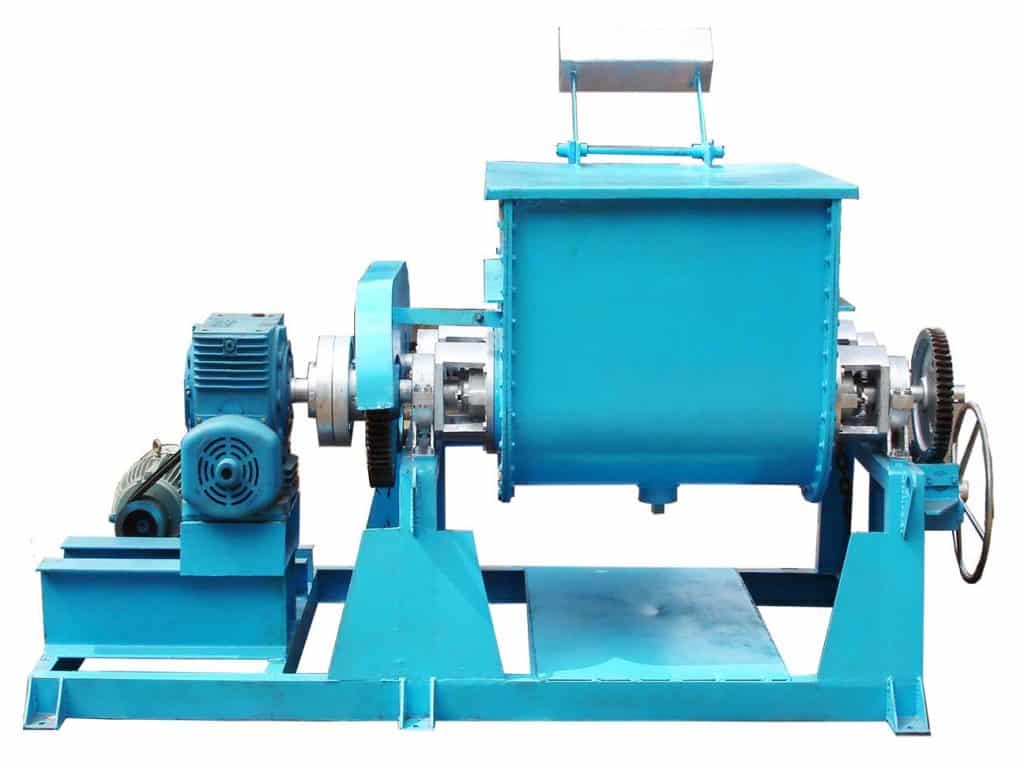

Sigma Mixer Description

Abster Equipments the modern and heavy duty, strong built Sigma mixer manufacturer to produce uniform mixing and kneading heavier viscosity materials. The Sigma mixture is suitable for many applications like mixing, kneading, Grinding, dispersion, drying etc. The sigma mixer have application to produce highly viscous materials like different kinds of Chemical, Dyes & Pigments, Paint, Polymers Plastic, Putties, Plastic, Pharmaceuticals, Printing ink, stiff pastes, adhesives, polyester Compounds, flush colors, brake lining compounds, resign, soap, PVC coatings, Rubber compounds, Confectionery, Magnetic Tape Coatings, Ceramic, Carbon Black, doughs,, Food Products, Fiber Glass, Grease, Lead Storage Battery, Soap & Detergent etc.

Sigma Mixer Operation

Sigma mixer, the

tangential action of mixing and kneading is thoroughly obtained by ‘Z’ (SIGMA) shaped

kneading blades, which rotates very accurately at different speed towards each

other causing product to be transferred from blade to blade. Discharge of the

mixed product is achieved by tilting the container or through the valves at the

bottom or by means of an extrusion screw below the container if provided

Salient Features

- Sigma Mixer is a Batch type Mixer

- In sigma mixer, Mixing Trough and Blades are

fabricated from mild steel, stainless steel 304 and 316 grade.

-

Blades of sigma mixers are

designed to obtain thorough mixing of high viscosity materials.

-

Sigma Mixers Blades are

machined to keep minimum equal gap between through walls and

blades.

-

Sigma mixers have fixed with Heavy-duty gears to sustaion of load of Kneading.

-

Shaft sealing into the stuffing

boxes is provided by Teflon Chevron Rings / PTFE breaded gland rope to prevent

leaking from blade ends.

-

Safety Guards and Grills are provided for maximum safety in sigma mixers.

Sigma Mixer Options

- GMP / Non GMP / models.

- Discharge in sigma mixers is done by tilting container / bottom sliding valves

/ bottom gates / flush bottom gate valves.

- Tilting in sigma mixers is done by hand liver / hand wheel with lead screw /

electrical arrangements / hydraulic systems.

- Lifting of lead either manually, with help of counter weights or hydraulically.

- ‘Z’ Type Spiral blade / Naben / double naben blades to circulate hot / cold

water in cases of heavy masses.

- Jacketed shell for heating or cooling by steam, oil, water etc. with fiber

glass insulation over the jacket.

- Spray system for liquid addition / gas purge.

- Flame proof / Non-flame proof electrical controls.